-

IDEAL REFRACTORYRAMMING SYSTEMS

IDEAL Refractory Ramming Systems including; wall rammer, bottom rammer, manuel and automatic ramming crane system is used in induction furnaces for ramming refractory mass with equal density and removes risks such as cracks and gas pockets risks in refractory. Ramming operation is completed in a very short time than other methods and life of refractory extends. More melting is done and induction furnace is used more efficent by shortening ramming operation time. Manpower is used more efficent and economic too. -

IDEAL WALLRAMMING MACHINE

It is used for wall refractory ramming operation of coreless induction furnaces. Furnaces, which have different capacities , can be rammed by only one machine with adjustable piston working diameter. Spring – loaded mechanism allows to ram conic formers. Standart products such as 2 pistons, 3 pistons and 5 pistons machines allows ramming from 500 kg. to 40 ton capacity induction furnaces. Special productions are available for greater capacity furnaces.Read More... -

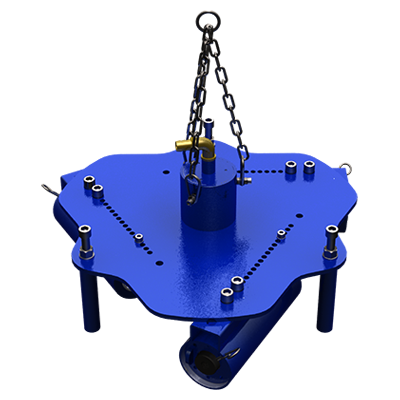

IDEAL BOTTOMRAMMING MACHINE

It is used for bottom refractory ramming operation of coreless induction furnaces. Different capacity of furnace bottoms can be rammed using one piston by changing adapter flanges. The body of the machine was consolidated with steel supports. Equal ramming is assured owing to “vibe-divide” technology, which is used in larger furnaces.Read More... -

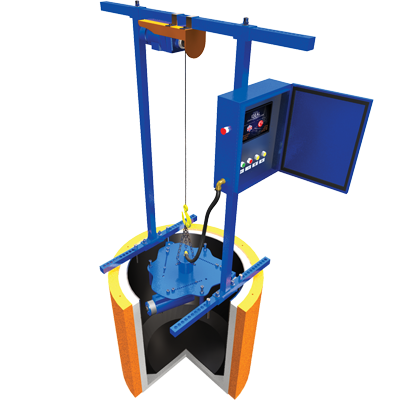

IDEALCRANE SYSTEMS

It can used both for bottom and wall ramming systems of any capacity coreless induction furnaces. Crane could be manual or automatic depends on request. PLC controlled panel which is especially preffered for larger capacity furnaces, has great advantages like calculating needed refractory amount, ramming duration and operation etc. There is no labour need while ramming process when automatic crane unit is used. It makes labour is used more efficent.Read More... -

IDEAL REFACTORYRAMMING SYSTEMS

IDEAL Refractory Ramming Systems General OverviewRead More...